27 May 2020

HOW A COMMUNITY EFFORT IN JARDÍN, COLOMBIA, GIVES FARMERS MORE TIME TO SPEND WITH THEIR FAMILIES AND SAVES PRECIOUS WATER.

For generations, coffee farmers in Colombia have processed their coffee individually. This process is sometimes artisanal, as well as time intensive. If done without all the right steps or equipment it can consume more water than needed; and if farmers are not careful, their wastewater can pollute rivers.

When you do it all yourself, it’s not always easy to keep things consistent, which means some farmers miss out on the premiums we pay for high-quality coffee produced.

The Mill in Colombia

AT A GLANCE

The mill has enabled coffee farmers to double the volume of Nespresso AAA Sustainable Quality™ Program quality coffee, secure a higher premium and increase progressively their net income by 17 percent.

To reduce the environmental impacts of coffee processing, while also improving the consistency of coffee quality, Nespresso and key partners built a new milling facility for one longstanding community of coffee farmers.

Nestled deep in the Andes, the new mill in Jardín, Colombia, has a centralised and more efficient process, bringing together around 200 farmers and saving them each up to four hours of processing a day. They also earn more as the mills allow for more consistent processing and higher quality beans. The facility saves around 60 percent of the water that was previously used and prevents pollution. Win-win.

Plus, better milling techniques at the Community Mill means we preserve the exceptional taste and aroma profiles required for your Nespresso Grand Cru coffees. Win-win-win.

01 Delivery

Once farmers have handpicked red coffee cherries, they deliver them to the mill, which is managed by a co-operative.

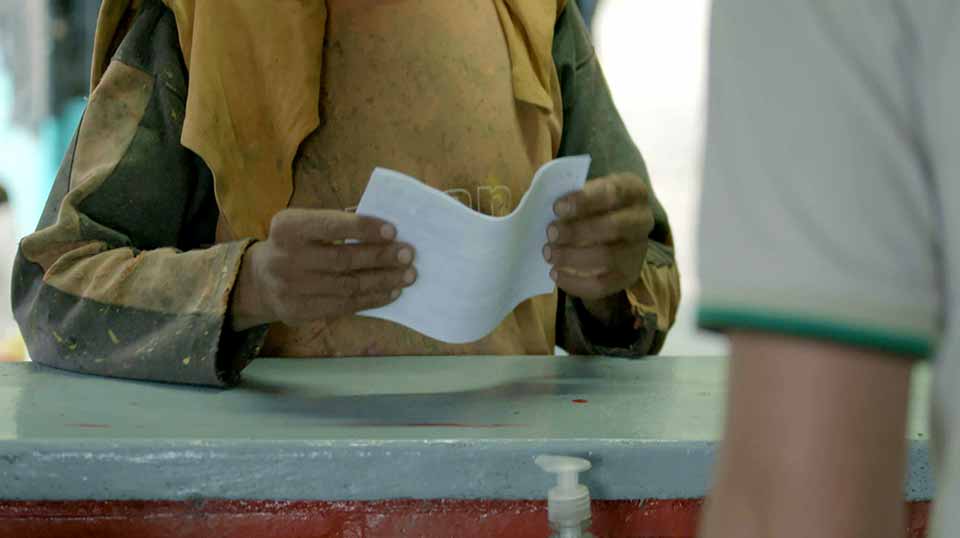

02 Inspection

A member of the co-operative takes a sample of the cherries and assesses how many red and green ones there are. Red cherries are the best, as they’re ripe and juicy.

03 Buying the cherries

The farmers are paid according to the percentage of good, red cherries they’ve brought. Since the mill was set up, Nespresso’s rejection rate of beans has fallen from 50 percent to zero as farmers now pick as many red cherries as possible.

04 Depulping

The cherries are put into a machine with rollers which take off their skin and outer pulp. The pulp is processed and distributed among the farmers to use as compost, another environmental benefit. The tightly controlled production process also ensures a high-quality bean.

05 Fermenting

As the beans are still covered in a “mucilage” (a sticky layer), they’re put into large fermentation tanks for 12 to 24 hours to remove it while capturing all the delicious fruity taste. The tanks are cylindrical, which means they’re easier to clean and less water is used. The beans are now known as parchment coffee.

06 Drying

The coffee beans are then sun-dried on patios about 20 minutes from the mill, where it’s much less rainy! The patios have a plastic roof, and sides which can be opened during the day and closed at night when the temperature drops. It takes around five days to sun-dry the parchment coffee.

07 Cleaning and saving water

The mill treats the wastewater generated from processing the cherries, so there’s no water pollution. The mill also saves a staggering 4.2 million litres of water a year, as farmers are no longer doing their own processing.

Community Coffee Processing

AT A GLANCE

We’re already starting to replicate the concept of community coffee processing in other regions of Colombia, for example in Gigante Huila

In the coming years, Nespresso will continue to make improvements to the Community Mill so it may benefit even more farmers. Best part? We are already starting to operate a second one in Gigante Huila, supporting new communities with climate friendly solutions. Drink up!

Related Articles

Let us bring the Nespresso Professional Coffee Experience to you

Recharge without charge. Book a free Nespresso Professional ‘coffee morning’ (or afternoon) to discover the benefits that premium coffee can bring to your business.

Book Now